Focal Point, Batala, Punjab

- GST NO. : 03BONPS6466L1Z7

CNC Metal Spinning Machine

Leading Manufacturers, Exporters, Wholesaler, Retailer, Distributor of CNC Metal Spinning Machine SSGS 1600, CNC Metal Spinning Machine SSGS200, CNC Metal Spinning Machine SSGS400, CNC Metal Spinning Machine SSGS600, CNC Metal Spinning Machine SSGS800 and CNC Metal Spinning Machine SSGS1000 from Batala.

| Business Type | Manufacturer, Supplier |

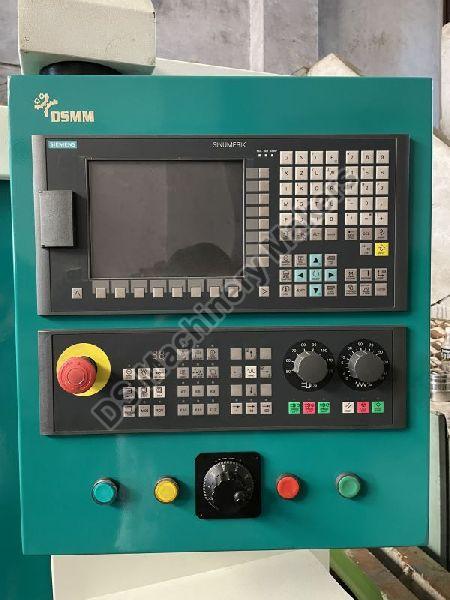

| Brand Name | DSMM |

| Material | Mild Steel |

| Model | SSGS1600 |

| Max. Dia Of Material | 1200 mm |

| X Travel Displacement | 710mm |

| Z Travel Displacement | 950mm |

| Thickness of Work Piece | Aluminium = .5 to 8mm Mild Steel = .5 to 4.5mm Copper = .5 to 6mm Stainless Steel = .5 to 3.5mm |

Preferred Buyer From

| Location | Worldwide |

Standard Configurations & Main Feature:-

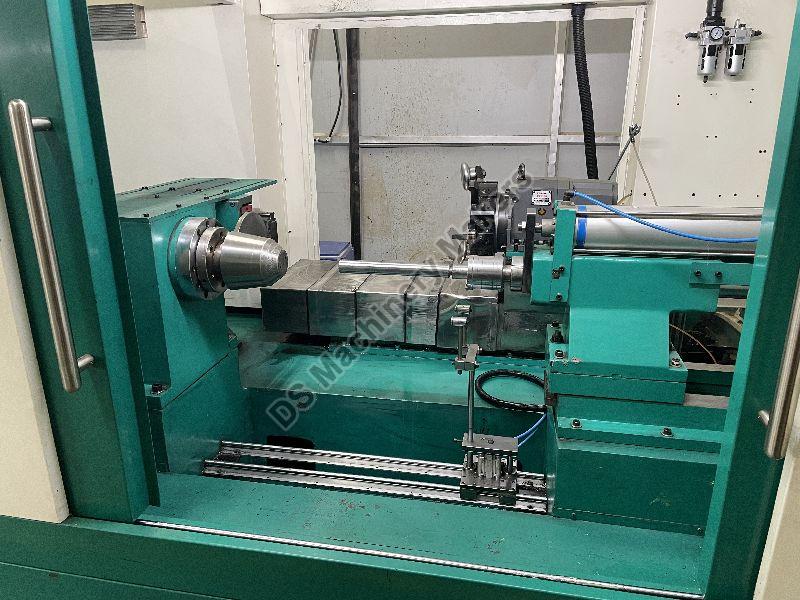

- CNC controlled

- Machine specialized tor spinning, shear forming and machining.

- One ortwo working slide

- Siemens 808D panel as standard CNC system which has USB port.

- Automatic Centering unit

- Stationarytrimming blade

- Automatic lubricant spray unit

- Automatic positioning of tailstock

- Precision ball screws ensure dynamic performance well and positioning accurately

- Siemens/Fanuc/delta make servo system

- Feeding axles are controlled by servo motors.

- Hydraulic & Pneumatic tailstock.

- Integrated automatic lubrication system makes the maintenance more reliable.

- Semi-enclosed shield for safe working.

The Function and Application Scope:-

CNC Spinning Machine is especially developed to spin kitchenware, lamps, auto Fittings, ventilations and art wares.

This machine is practical, professional and strong. It has high production efficiency and can complete horn, bucket, cone type, parabolic products.

The machine can spin many materials such as steel, alloy and copper etc. It has solved the traditional problems such as lack of skilled workers. With advanced digital control, it is easy to operate.

The machine can improve the production efficiency, machining accuracy and saving the cost of human resources. It is the ideal processing machine for light, automobile, military, mechanic and other manufacturing industries.

Note:- As improvements are made from time to time these specifications are subject to change without notice

| Business Type | Manufacturer, Supplier |

| Brand Name | DSMM |

| Model | SSGS200 |

| Max. Dia Of Material | 200 mm |

| X Travel Displacement | 100 mm |

| Z Travel Displacement | 200 mm |

| Thickness of Work Piece | Aluminium = .5 to 3mm Mild Steel = .5 to 1.5mm Copper = .5 to 3mm Stainless Steel = .5 to 1.5 |

| Guide Rail Type | Linear Guide Rail |

| Axis motor | Ac servo motor |

| Control system | Siemens PPU151 |

| Servo Power X/Z | 6 NM X 7.5 NM |

| Pushing force for z axis | 25kN |

| Pushing force for x axis | 25kN |

| Spindle Speed | 2000 rpm |

| Travel of Tailstock | 200 mm |

| Taper of tail stoke quill | MT5 |

| Amount of Tool | 4 |

| Spindle Motor Power | 7.5 hp |

| Hand Tools | 1 set |

Preferred Buyer From

| Location | Worldwide |

The Function and Application Scope:

- CNC Spinning Machine is especially developed to spin kitchenware, lamps, auto Fittings, ventilations and art wares.

- This machine is practical, professional and strong. It has high production efficiency and can complete horn, bucket, cone type, parabolic products.

- The machine can spin many materials such as steel, alloy and copper etc. It has solved the traditional problems such as lack of skilled workers. With advanced digital control, it is easy to operate.

- The machine can improve the production efficiency, machining accuracy and saving the cost of human resources. It is the ideal processing machine for light, automobile, military, mechanic and other manufacturing industries.

Standard Configurations & Main Features:

SINGLE ROLLER

- Siemens panel as standard CNC system which has USB port and safety alarms.

- Automatic pneumatic Centering unit

- Precision ball screws ensure dynamic performance well and positioning accurately.

- Siemens make servo system

- Feeding axles are controlled by servo motors.

- Pneumatic tailstock.

- Integrated automatic lubrication system makes the maintenance more reliable.

- Semi-enclosed shield for safe working.

- Pressure gauge for measure the pressure.

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Wholesaler, Trader, Distributor |

| Brand Name | DSMM |

| Model | SSGS400 |

| Max. Diameter Of Material | 400 mm |

| X Travel Displacement | 210 mm |

| Z Travel Displacement | 350 mm |

| Thickness of Work Piece | Aluminium = .5 to 4mm Mild Steel = .5 to 2.5mm Copper = .5 to 3.5mm Stainless Steel = .5 to 2 |

| Guide Rail Type | Linear Guide Rail |

| Axis motor | Ac servo motor |

| Control system | Siemens PPU151 |

| Servo Power X/Z | 8NM X 11NM |

| Pushing force for x/z axis | 30kN |

| Spindle Speed | 2500 rpm |

| Travel of Tailstock | 350 mm |

| Taper of tail stoke quill | MT5 |

| Amount of Tool | 4 |

| Spindle Motor Power | 10 hp |

| Hand Tools | 1 set |

Preferred Buyer From

| Location | Worldwide |

Standard Configurations & Main Feature:-

- CNC controlled

- Machine specialized tor spinning, shear forming and machining.

- One ortwo working slide

- Siemens 808D panel as standard CNC system which has USB port.

- Automatic Centering unit

- Stationarytrimming blade

- Automatic lubricant spray unit

- Automatic positioning of tailstock

- Precision ball screws ensure dynamic performance well and positioning accurately

- Siemens/Fanuc/delta make servo system

- Feeding axles are controlled by servo motors.

- Hydraulic & Pneumatic tailstock.

- Integrated automatic lubrication system makes the maintenance more reliable.

- Semi-enclosed shield for safe working.

The Function and Application Scope:-

CNC Spinning Machine is especially developed to spin kitchenware, lamps, auto Fittings, ventilations and art wares.

This machine is practical, professional and strong. It has high production efficiency and can complete horn, bucket, cone type, parabolic products.

The machine can spin many materials such as steel, alloy and copper etc. It has solved the traditional problems such as lack of skilled workers. With advanced digital control, it is easy to operate.

The machine can improve the production efficiency, machining accuracy and saving the cost of human resources. It is the ideal processing machine for light, automobile, military, mechanic and other manufacturing industries.

Note:- As improvements are made from time to time these specifications are subject to change without notice

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Wholesaler |

| Brand Name | DSMM |

| Model | SSGS600 |

| Max. Diameter Of Material | 600mm |

| X Travel Displacement | 210 mm |

| Z Travel Displacement | 550 mm |

| Thickness of Work Piece | Aluminium = .5 to 6mm Mild Steel = .5 to 3mm Copper = .5 to 5 mm Stainless Steel = .5 to 3 mm |

| Guide Rail Type | Linear Guide Rail |

| Axis motor | Ac servo motor |

| Control system | Siemens ppu161 |

| Servo Power X/Z | 11NM X 15NM |

| Pushing force for x/z axis | 35kN |

| Spindle Speed | 2800 rpm |

| Travel of Tailstock | 400 mm |

| Taper of tail stoke quill | MT5 |

| Amount of Tool | Sync 2+ |

| Spindle Motor Power | 10 hp |

| Hand Tools | 1 set |

Preferred Buyer From

| Location | Worldwide |

Standard Configurations & Main Feature:-

- CNC controlled

- Machine specialized tor spinning, shear forming and machining.

- One ortwo working slide

- Siemens 808D panel as standard CNC system which has USB port.

- Automatic Centering unit

- Stationarytrimming blade

- Automatic lubricant spray unit

- Automatic positioning of tailstock

- Precision ball screws ensure dynamic performance well and positioning accurately

- Siemens/Fanuc/delta make servo system

- Feeding axles are controlled by servo motors.

- Hydraulic & Pneumatic tailstock.

- Integrated automatic lubrication system makes the maintenance more reliable.

- Semi-enclosed shield for safe working.

The Function and Application Scope:-

CNC Spinning Machine is especially developed to spin kitchenware, lamps, auto Fittings, ventilations and art wares.

This machine is practical, professional and strong. It has high production efficiency and can complete horn, bucket, cone type, parabolic products.

The machine can spin many materials such as steel, alloy and copper etc. It has solved the traditional problems such as lack of skilled workers. With advanced digital control, it is easy to operate.

The machine can improve the production efficiency, machining accuracy and saving the cost of human resources. It is the ideal processing machine for light, automobile, military, mechanic and other manufacturing industries.

Note:- As improvements are made from time to time these specifications are subject to change without notice

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Wholesaler |

| Brand Name | DSMM |

| Model | SSGS800 |

| Max. Dia Of Material | 800 mm |

| X Travel Displacement | 210 mm |

| Z Travel Displacement | 650 mm |

| Thickness of Work Piece | Aluminium = .5 to 7mm Mild Steel = .5 to 4mm Copper = .5 to 6mm Stainless Steel = .5 to 3.5mm |

| Guide Rail Type | Linear Guide Rail |

| Axis motor | Ac servo motor |

| Control system | Siemens 808 |

| Servo Power X/Z | 15NM X 18NM |

| Pushing force for x/z axis | 40kN |

| Spindle Speed | 2500 rpm |

| Travel of Tailstock | 450 mm |

| Taper of tail stoke quill | MT5 |

| Amount of Tool | Sync 2+ |

| Spindle Motor Power | 15 hp |

| Hand Tools | 1 set |

| Product Code | SSGS 800 |

Preferred Buyer From

| Location | Worldwide |

Standard Configurations & Main Feature:-

- CNC controlled

- Machine specialized tor spinning, shear forming and machining.

- One ortwo working slide

- Siemens 808D panel as standard CNC system which has USB port.

- Automatic Centering unit

- Stationarytrimming blade

- Automatic lubricant spray unit

- Automatic positioning of tailstock

- Precision ball screws ensure dynamic performance well and positioning accurately

- Siemens/Fanuc/delta make servo system

- Feeding axles are controlled by servo motors.

- Hydraulic & Pneumatic tailstock.

- Integrated automatic lubrication system makes the maintenance more reliable.

- Semi-enclosed shield for safe working.

The Function and Application Scope:-

CNC Spinning Machine is especially developed to spin kitchenware, lamps, auto Fittings, ventilations and art wares.

This machine is practical, professional and strong. It has high production efficiency and can complete horn, bucket, cone type, parabolic products.

The machine can spin many materials such as steel, alloy and copper etc. It has solved the traditional problems such as lack of skilled workers. With advanced digital control, it is easy to operate.

The machine can improve the production efficiency, machining accuracy and saving the cost of human resources. It is the ideal processing machine for light, automobile, military, mechanic and other manufacturing industries.

Note:- As improvements are made from time to time these specifications are subject to change without notice

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Wholesaler |

| Brand Name | DSMM |

| Model | Ds 1000 |

| Max. Dia Of Material | 1000 mm |

| X Travel Displacement | 510 mm |

| Z Travel Displacement | 750 mm |

| Thickness of Work Piece | Aluminium = .5 to 8mm Mild Steel = .5 to 4.5mm Copper = .5 to 6mm Stainless Steel = .5 to 3.5mm |

| Guide Rail Type | Linear Guide Rail |

| Axis motor | Ac servo motor |

| Control system | Siemens 808D |

| Servo Power X/Z | 20NM X 15NM |

| Pushing force for x/z axis | 60KN |

| Spindle Speed | 1500 rpm |

| Travel of Tailstock | 500 mm |

| Taper of tail stoke quill | MT5 |

| Amount of Tool | Sync 2+ |

| Spindle Motor Power | 20 hp |

| Hand Tools | 1 set |

| Product Code | SSGS 1000 |

Preferred Buyer From

| Location | Worldwide |

Standard Configurations & Main Feature:-

- CNC controlled

- Machine specialized tor spinning, shear forming and machining.

- One ortwo working slide

- Siemens 808D panel as standard CNC system which has USB port.

- Automatic Centering unit

- Stationarytrimming blade

- Automatic lubricant spray unit

- Automatic positioning of tailstock

- Precision ball screws ensure dynamic performance well and positioning accurately

- Siemens/Fanuc/delta make servo system

- Feeding axles are controlled by servo motors.

- Hydraulic & Pneumatic tailstock.

- Integrated automatic lubrication system makes the maintenance more reliable.

- Semi-enclosed shield for safe working.

The Function and Application Scope:-

CNC Spinning Machine is especially developed to spin kitchenware, lamps, auto Fittings, ventilations and art wares.

This machine is practical, professional and strong. It has high production efficiency and can complete horn, bucket, cone type, parabolic products.

The machine can spin many materials such as steel, alloy and copper etc. It has solved the traditional problems such as lack of skilled workers. With advanced digital control, it is easy to operate.

The machine can improve the production efficiency, machining accuracy and saving the cost of human resources. It is the ideal processing machine for light, automobile, military, mechanic and other manufacturing industries.

Note:- As improvements are made from time to time these specifications are subject to change without notice